|

EQUIPMENT FOR

|

|

SYSTEMS FOR AVTOMATIZATION. |

|

SHOT BLASTING MACHINES WITH ROTATING HOOK |

|

OPTIMIZED

|

|

METAL SURFACE CLEANING MACHINES |

|

ATEX FILTERS |

|

STANDARD SHOTBLASTING MACHINES ON STOCK

|

|

ROBOTIZATION AND AVTOMATIZATION IN DIFFERENT PRODUCTIONS |

|

SMART &

|

|

SIAPRO TEST CENTER

|

|

TUNNEL OVERHEAD

|

|

TRANSPORT SYSTEMS

|

d.thumb-540x164.jpg) |

HUGE MACHINES AND LINES FOR SHOTBLASTING AND PAINTING |

|

EQUIPMENT FOR

|

Siapro Group

There are two companies in the Siapro group that are strongly linked by ownership through majority ownership. With the purchase in 2022, Siapro d.o.o. became the majority owner of company Strojrem d.o.o. from Croatia. With the purchase, we acquired additional engineering and production capacities. We have now more than 75 highly professional employees and as much as 3,860 m2 of covered production areas. The main sales program of Strojrem is the production of various conveyors for the transport of loose or bulky materials. The proximity of Zagreb airport (50 min drive) further improves the conditions for great communication with business partners and customers.

There are two companies in the Siapro group that are strongly linked by ownership through majority ownership. With the purchase in 2022, Siapro d.o.o. became the majority owner of company Strojrem d.o.o. from Croatia. With the purchase, we acquired additional engineering and production capacities. We have now more than 75 highly professional employees and as much as 3,860 m2 of covered production areas. The main sales program of Strojrem is the production of various conveyors for the transport of loose or bulky materials. The proximity of Zagreb airport (50 min drive) further improves the conditions for great communication with business partners and customers.

Turn key Engineering projects

Our services are professional, solutions reflect the experience. In the field of foundry equipment we are an independent company associated with various partner companies.

VIDEO Company presentation VIDEO Foundry Equipment VIDEO Shotblasting Machines

VIDEO project example-production of shotblasting machine and FAT test, machine 100% made in Slovenia

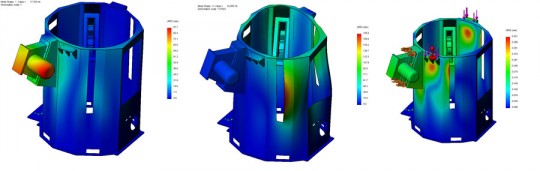

Guaranteed the highest demands of Shotblasting, Shotpeening and mechanical Eco dry pickling

Our new E-ECO Complete Process Monitoring Technology (CPMT) is Surface Treatment Revolutionary Technology. With the latest E-ECO smart blasting wheel and AAD automatic abrasive dosing integrated into a Complete Process Monitoring we can provide the highest demands of Shotblasting/Shotpeening/Mechanical Pickling.

Stock Machines - Shotblasting Machines

E-ECO highly efficient smart blasting turbines - Siapro Development, Price Optimization (Basic, Junior, Superior Solutions for shotblasting), Good Price for Delivered Quality and Robust Construction, More info...Shot blasting Applications

Shotblasting is used in almost every industry that uses metal such is foundry, forge, construction, iron works and rolling mils, aluminium industry, automotive industry, metal surface protection, heat treatment of metal, shipbuilding, aerospace, shotpeening, rail industry, production fo plates, pipes, springs and others.Different media or steel shots (abrasive) and different shot blasting technology is selected for treatment different metal surfaces.

Subscribe to our You Tube channel here.

|

A New Step Towards Development: Renovation and Expansion of HeadquartersWe started with the renovation and extension of our office and workshop facilities at the headquarters of Siapro d.o.o., Postaja 9, 5216 Most na Soči, Slovenia. This important step reflects our growth and development over the past 30 years, as we have outgrown existing capacities with the team and scope of work. The expansion will ensure better working conditions and foster the company's growth. The project includes 200 m² of additional storage space, 14 new workplaces and as much as 260 m² of new areas for offices and administration, which will be spread over two floors. In addition, working conditions will also improve in common areas - with a modern meeting room, a larger dining room and more comfortable spaces for socializing and collaboration. We look forward to a future in more modern facilities, enabling greater efficiency, satisfaction, and team cohesion. In the next two years, we also plan to expand our production facilities in Croatia. With these steps, we are strengthening the foundations for future success and consolidating our role on the global market. Photo: Simulation of the renovated building |

|

Future-Ready design with Robotic Upgrade CapabilityOur latest machine, now operational for a customer in Slovenia, embodies forward-thinking innovation. Designed for manual operation today, it offers seamless adaptability for robotic upgrades in the future, ensuring long-term efficiency and scalability. Purpose-built for surface hardening of gears and shafts, this machine features: Do you have more questions? We would like to answer. |

|

Make your Car or Truck Wheel Rims Look Like New Again with Our Advanced Shot Blasting Machines!Are you in the automotive service, wheel manufacturing, or refurbishment industry? With our shot blasting machines, you can restore car and truck wheel rims to their original, like-new condition – ready to impress and perform! |

|

Dispatchment of a new machine from Siapro productionTable shotblastig machine. |

|

Invitation to FUNDIEXPO 2024 in MexicoWe are excited to invite you to FUNDIEXPO 2024, the premier event for the foundry and metal casting industry in Latin America! This year’s event will feature the latest innovations and solutions in the field, and we are eager to showcase our advanced technologies.

|

|

Great news from Siapro Group's metal production company Strojrem!We're thrilled to announce that our production capacities are fully booked and running at 100%! From conveyor systems and shot blasting machines to hydro power plant equipment, our facilities are operating at maximum efficiency to meet the growing demand. It's fantastic to witness our team fully engaged, showcasing the strength and capability of our production expertise. This is a true testament to our commitment to quality and reliability. Proud to share this milestone with all of you! |

SIAPRO d.o.o.

Postaja 95216 MOST NA SOČI

Slovenia, Europe

T: +386 5 3841 632

E: info@siapro.si

More contacts>>

Follow us on

References

|

.thumb-200x110.jpg) |

|

|

.thumb-200x110.jpg) |

|

|