Siapro Test Centre in central Europe for testing abrasives and surface technology with shotblasting, shotpeening and ECO-DRY mechanical pickling process

What we offer?

- Testing metal, aluminum and other abrasives for blasting with turbine shotblasting machines.

- Testing and determining the technology for shotblasting of individual work pieces according to customer requirements.

- Durability wear tests of machine parts from all blasting equipment manufacturers.

You can benefit from our expertise

You can benefit from our expertise

Thanks to the knowledge and practice accumulated over the years and shared with ours many customers, Siapro has been developed a waste range of applications for surface treatment. In order to lead the way with the developments and technology we established developing and research centre for Advanced Surface Technology. Here our customers have an opportunity to find the optimal technology of surface treatment for its products. Testing shootpening

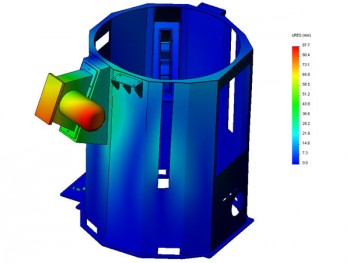

Technological development in surface cleaning and finishing shows us the extreme importance of the usability of the parts needed to be treated as do necessity for maximum regulation of correlations between wear resistance of materials, costs reduction, ecology and surface treatment efficiency. With testing and simulations we can find the best solution.

Technological development in surface cleaning and finishing shows us the extreme importance of the usability of the parts needed to be treated as do necessity for maximum regulation of correlations between wear resistance of materials, costs reduction, ecology and surface treatment efficiency. With testing and simulations we can find the best solution.What do we need?

1. Your metalworking requirements.2. Your abrasive.

3. Your workpieces.

What will you get?

a) Analytical report with recommendations for practical action.b) Assurance that your machine operates efficiently at the lowest possible cost.

c) Calculation of annual abrasive consumption and annual spare parts costs.

d) If you invest in new shotblasting machine, we offer you a new Siapro machine optimized for maximum efficient operation under your conditions.

Advantages of Test center Siapro are:

1. Simulation of industrial conditions on machines2. 25 years of experience, skilled engineers

3. Ideal location in the middle of Europe

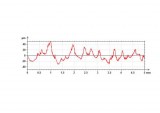

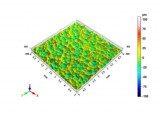

4. Advanced approach in testing: 3D scanning, 3D modelling, surface measurement, testing different abrasives, testing machine optimal settings, metallographic, spectrometer analyse, chemical analyse, etc.

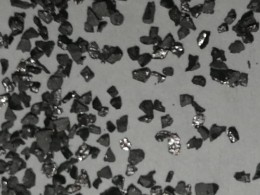

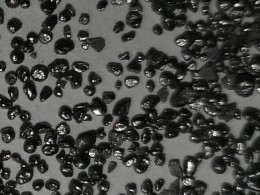

New and used abrasive:

General info about Siapro surface treatment technology

Siapro's Complete Process Monitoring Technology (CPMT) and E-ECO Shot Blasting Technology developed in last year’s gives us possibilities to reach the most advanced surface treatment for different applications.Furthermore, whenever possible Siapro always invest our time and resources in setting up strong partnerships with the customer. Our common aim is continuous developing and improving investments and processes due possible to changes in production process- real situations can change during different productions demands over years. And we have obtained very rewarding results to this approach.

Our applications can be divided into the following main categories:

Our applications can be divided into the following main categories:1. Cleaning and removal of oxides subsequent

2. Rust removal

3. Descaling

4. Surface finishing

5. Deburring

6. Surface preparation before painting

7. Roughness control

8. Controlling material removal

We will not give here the whole overview of applications for the shot blasting and shot-peening machines. But we will recommend carrying out feasibility tests on the pieces to be treated. Our common aim is to find the most cost-effective and efficient solutions for each concrete surface demand or a specific piece needed to be treated.

That is why we operate with Siapro Surface Technology Test Centre with skilled technicians who perform peening and shot blasting tests in order to help customers identify the best and most cost-effective solution to obtain the best expected result.

In general in modelling appropriate application we should be aware of:

- Inferior quality of the abrasive agent (shot) and insufficient purity of the abrasive mixture can be responsible for low effectiveness of shot blasting.

- We should not fail to fully recognise the importance of proper diagnostics of the shot blasting process in industrial conditions as do optimizing surface treatment process for low as do intensive productions

- Analytical studies should be conducted to optimise the process and mechanical parameters of the system components and to identify the key phenomena involved in shot-blasting.

- We should determine the optimal shape of the shot stream in terms of its geometric, kinetic and dynamic parameters, which is not always in correlation with ware resistant parts of the machine.

- The wearing of major machine components and of the blasting agent and quality of shot treated surfaces should not be misinterpreted.

- We need to take into account all factors involved in the process within the frame of a comprehensive methodology because our common aim is to reduce cost with maximum output of blasting part.

- Trial runs of the equipment, testing before delivery.

- The test is also the best way to formulate and apply the available testing methods to the engineering practice in industrial conditions.

- In our Test Centre we are developing and testing also new components for surface treatment equipment – CPMT (Complete Process Monitoring Technology) in general.

- We are testing also E-ECO DRY pickling of steel strips.

CATALOGUES

A4_Abrasive and surface technology Test center_Siapro_eng_2024_distribution (.pdf 2.3MB)

A4_Abrasive and surface technology Test center_Siapro_eng_2024_distribution (.pdf 2.3MB) SIAPRO d.o.o.

Postaja 95216 MOST NA SOČI

Slovenia, Europe

T: +386 5 3841 632

E: info@siapro.si

More contacts>>

Follow us on

References

|

|

.thumb-200x110.jpg) |

|

|

.thumb-200x110.jpg) |

|