|

TUNNEL OVERHEAD

|

|

ATEX FILTERS |

|

SYSTEMS FOR AVTOMATIZATION. |

|

OPTIMIZED

|

|

METAL SURFACE CLEANING MACHINES |

d.thumb-540x164.jpg) |

HUGE MACHINES AND LINES FOR SHOTBLASTING AND PAINTING |

|

STANDARD SHOTBLASTING MACHINES ON STOCK

|

|

SHOT BLASTING MACHINES WITH ROTATING HOOK |

|

TRANSPORT SYSTEMS

|

|

SIAPRO TEST CENTER

|

|

EQUIPMENT FOR

|

|

SMART &

|

|

ROBOTIZATION AND AVTOMATIZATION IN DIFFERENT PRODUCTIONS |

|

TUNNEL OVERHEAD

|

Engineering Projects and Industrial Equipment

We specialize in executing engineering projects and manufacturing equipment for blasting, foundry, steelmaking, the machinery industry, and production process automation. We also produce hydropower plants of up to 10 MW. Our offering includes comprehensive engineering and the production of machines and equipment – from professional consulting and design to installation and maintenance. We have been present on the market for over 30 years.

Siapro Group

In 2022, Siapro d.o.o. became the majority owner of the Croatian company Strojrem d.o.o., thereby expanding our engineering and production capacities. Today, the Group brings together more than 75 experts and operates 3,860 m² of production facilities. Strojrem specializes in the manufacturing of conveyors for bulk and piece materials

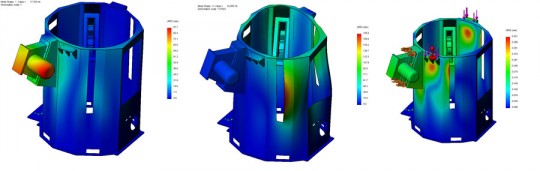

Meeting the Highest Standards in Blasting, Peening, and Mechanical Metal Cleaning

In the field of metal cleaning, our E-ECO CPMT technology ensures superior process control in metal treatment. With the latest E-ECO blasting turbine and AAD valve, we guarantee the highest quality in metal blasting.

Standard and Custom-Made Equipment Tailored to Customer Needs

We offer standard blasting machines as cost-optimized solutions, as well as fully customized machines. Projects are delivered on a turnkey basis.

VIDEO project example-production of shotblasting machine and FAT test, machine 100% made in Slovenia

Machines in Stock

Certain blasting machines are always available from stock.Subscribe to our You Tube channel here.

|

Visit to Strojrem in CroatiaEmployees from Siapro Slovenia visited our company Strojrem in Croatia, an important part of the Siapro Group. During the visit to the production of our equipment, we confirmed that the strong connection within the Group brings many advantages to our customers – from top quality and reliability to innovative solutions created through combined knowledge and experience. |

|

Siapro d.o.o. has been successfully certified with ISO 9001:2015At Siapro d.o.o., we place great emphasis on the quality of our products and services. Therefore, we are especially proud to announce that we have implemented a quality management system and obtained the ISO 9001:2015 certification. This international certification demonstrates our strong commitment to quality management, continuous improvement, and customer satisfaction. It means that every product and service we provide meets the highest standards of quality, reliability, and consistency. Siapro d.o.o., an innovative engineering company in the fields of foundry, metal surface treatment, and energy, has received co-financing for eligible costs under the voucher “V3 – Voucher for Obtaining Certificates.” The investment is co-financed by the European Union. |

|

Siapro Company Have Received the Platinum Credit Rating of Excellence!We are proud to announce that we have received the Platinum Creditworthiness Certificate of Excellence, which signifies that our company has an outstanding credit rating and is among the most reliable and successful companies in the country.This recognition is awarded to companies that have achieved the Golden Creditworthiness Certificate (AAA) for three or more consecutive years. |

|

Great Memories from Visit to Strojrem in Croatia, Siapro Production FacilitySharing some great memories from our last visit to Strojrem in Croatia, our production facility for shot blasting machines. It was a great opportunity to see the production first-hand, connect with the team and exchange ideas. Always proud of the expertise and dedication within the Siapro Group! |

|

Renovation and expansion in progress at Siapro!Our building at our headquarters is getting a fresh new look - and we’re moving into upgraded offices in the future!We’re excited for this new chapter, with more space to grow, collaborate and innovate. |

SIAPRO d.o.o.

Postaja 95216 MOST NA SOČI

Slovenia, Europe

T: +386 5 3841 632

E: info@siapro.si

More contacts>>

Follow us on

References

|

|

|

.thumb-200x110.jpg) |

.thumb-200x110.jpg) |

|

|